3D printer filaments are the core of additive manufacturing, offering versatility and a wide range of applications. They determine print quality, durability, and the overall success of projects, from prototypes to functional parts.

What Are 3D Printer Filaments?

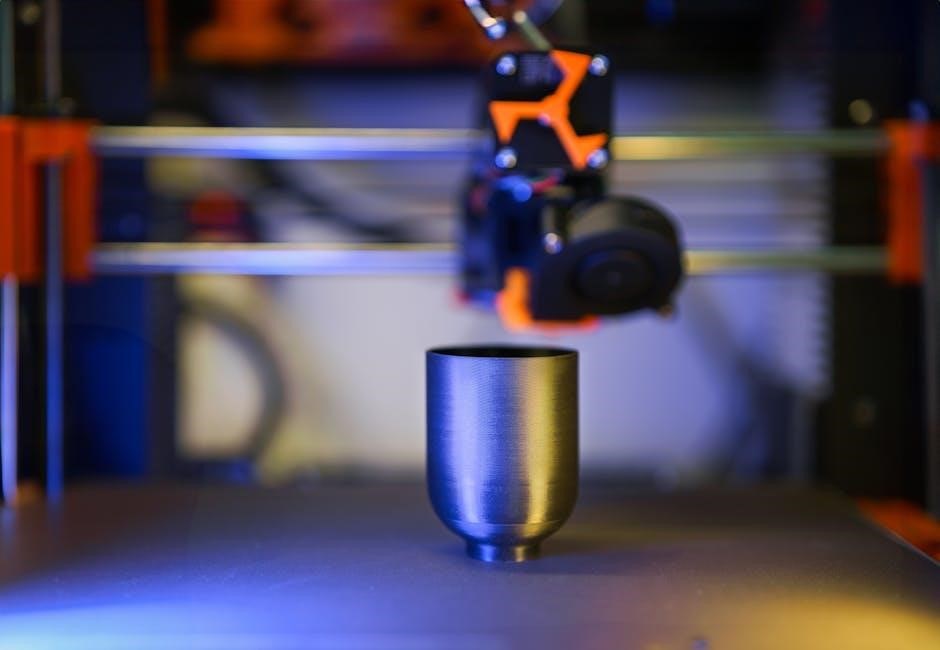

3D printer filaments are thermoplastic materials used as the primary feedstock in fused deposition modeling (FDM) 3D printing. They are produced in spool form and come in various diameters, such as 1.75mm or 2.85mm. Filaments serve as the raw material that is melted and extruded by the printer to create the final printed object layer by layer. Common types include PLA, ABS, PETG, and Nylon, each offering unique properties like flexibility, strength, or thermal resistance. The choice of filament depends on the desired outcome, such as durability, aesthetics, or specific functional requirements; Proper handling and storage of filaments are crucial to maintain their quality and printing performance. Understanding the characteristics of different filaments is essential for achieving successful and consistent 3D printing results.

Common Types of Filaments

Among the most widely used 3D printing filaments are PLA, ABS, PETG, and Nylon. PLA (Polylactic Acid) is biodegradable and ideal for eco-friendly prints, offering good layer adhesion and minimal warping. ABS (Acrylonitrile Butadiene Styrene) is durable and impact-resistant, commonly used for functional parts but requires higher temperatures. PETG combines the benefits of PLA and ABS, providing excellent strength, flexibility, and thermal stability. Nylon is known for its high strength, abrasion resistance, and durability, making it suitable for industrial applications. Additionally, specialty filaments like PVA (for water-soluble support) and Metal-filled filaments (for aesthetic or conductive properties) expand the possibilities of 3D printing. Each type has unique properties, catering to different project needs and printer capabilities, ensuring versatility in additive manufacturing.

Factors to Consider When Choosing a Filament

Selecting the right filament involves evaluating temperature requirements, material properties, and intended applications. Compatibility with your printer and project goals ensures optimal results and durability in prints.

Temperature Requirements

Temperature plays a crucial role in 3D printing. Each filament type has specific extrusion and bed temperature requirements. For example, PLA typically requires lower temperatures, around 190-220°C for the extruder and 60-80°C for the bed, while PETG needs slightly higher settings, around 230-250°C for the extruder and 80-100°C for the bed. ABS requires even higher temperatures, often around 250-270°C for the extruder and 100-120°C for the bed. Proper temperature settings ensure consistent extrusion, prevent warping, and improve adhesion. Using a heated enclosure can maintain a stable environment, especially for materials like ABS. Incorrect temperature settings can lead to issues such as stringing, layer separation, or failed prints. Always consult the filament manufacturer’s guidelines for precise temperature recommendations to achieve optimal printing results.

Material Properties

Material properties are essential for selecting the right filament. PLA is brittle but easy to print, while ABS is stronger and impact-resistant but requires higher temperatures. PETG offers a balance of strength, flexibility, and layer adhesion. Flexible filaments like TPU and TPE are ideal for elastic parts, while nylon is durable and resistant to abrasion. Carbon fiber-infused filaments provide added strength and stiffness, making them suitable for structural parts. Wood-based filaments mimic the appearance of wood, and metal-filled filaments add weight and a metallic finish. Each material’s properties, such as thermal resistance, flexibility, and moisture absorption, influence their suitability for specific applications. Understanding these properties helps in achieving desired print outcomes and ensures compatibility with the printer setup. Proper material selection is key to optimizing print quality and functionality.

Intended Application

The intended application of a 3D printed object plays a crucial role in selecting the appropriate filament. For instance, prototypes and decorative items often use PLA due to its ease of printing and vibrant color options. ABS, on the other hand, is favored for functional parts requiring durability and impact resistance. PETG strikes a balance, offering strength and flexibility for everyday use. Flexible filaments like TPU are ideal for elastic components such as seals or wearable items. Specialized filaments like conductive PLA or metal-filled options are chosen for specific purposes, such as electronics or aesthetic pieces. The application dictates the required strength, flexibility, and visual appeal, ensuring the final product meets its intended use. Choosing the right filament for the job enhances functionality and user satisfaction. This step is vital for achieving successful and purpose-driven prints. Proper filament selection aligns the print’s capabilities with its intended use case.

Setting Up Your 3D Printer for Different Filaments

Setting up your 3D printer for different filaments requires adjusting temperature, speed, and bed preparation. Ensure compatibility with your printer’s specifications for optimal results.

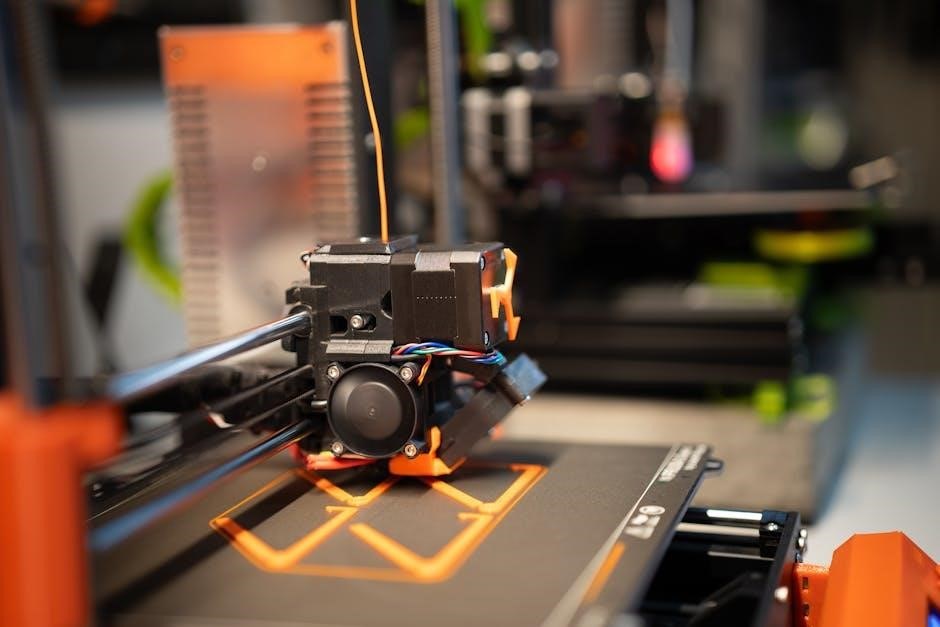

Calibrating Your Printer

Calibrating your 3D printer is essential for achieving accurate prints. Begin with bed leveling to ensure even adhesion. Adjust the Z-offset to set the correct first-layer height. Check the extruder steps to ensure consistent filament flow. Perform a test print to verify calibration accuracy. For precise results, use calibration tools like a leveling mat or a bed spring adjustment guide. Ensure the print bed is clean and free from debris. Proper calibration prevents issues like adhesion problems or layer shifting. Regular maintenance, such as checking belts and pulleys, ensures smooth operation. Refer to your printer’s user guide for specific calibration procedures. A well-calibrated printer guarantees high-quality prints and minimizes waste. Always calibrate before switching filaments or after significant printer modifications. This step is crucial for maintaining consistency and achieving professional-level results in your 3D printing projects.

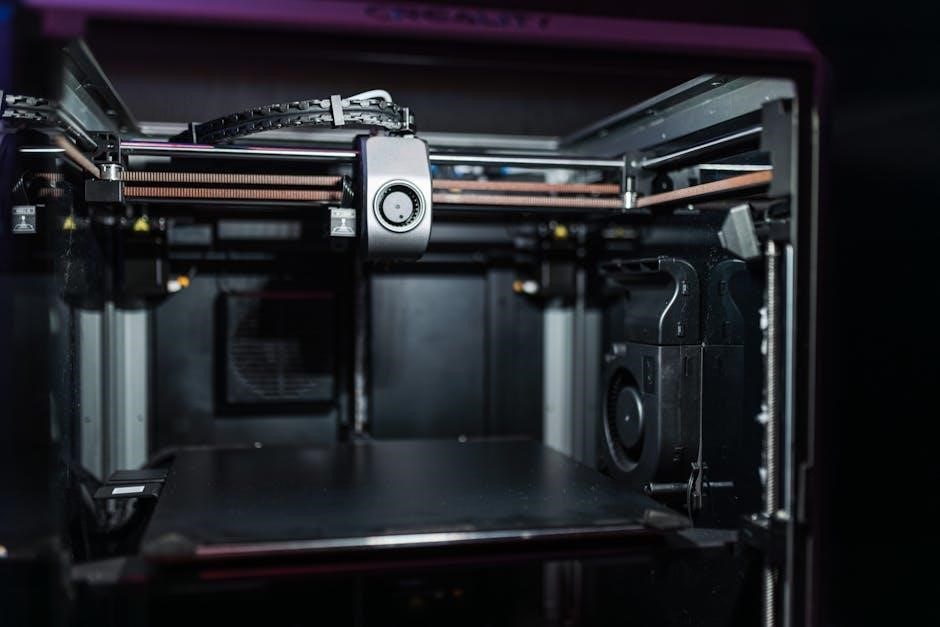

Preparing the Print Bed

Preparing the print bed is crucial for ensuring proper adhesion and a successful print. Start by cleaning the bed thoroughly with isopropyl alcohol to remove dirt, oils, or residue. For enhanced adhesion, apply a thin, even layer of adhesive such as boron carbide glass spray, PEI sheet adhesive, or a PVA glue stick. Allow the adhesive to dry completely before starting the print. For filaments like PETG or ABS, a heated bed with a temperature of 60-90°C is recommended. For PLA, a heated bed is optional but can improve adhesion. Ensure the bed is level and free of debris. Proper preparation prevents warping, delamination, and failed prints. Always check the filament-specific requirements for optimal results. A well-prepared print bed ensures a strong foundation for your 3D printing projects, leading to better print quality and durability.

Drying Filaments

Drying filaments is essential to maintain their quality and printing performance. Moisture absorption can lead to issues like bubbles, stringing, or poor layer adhesion. To dry filaments, place them in a well-ventilated area with low humidity or use a food dehydrator at 50-60°C for 4-6 hours. For critical applications, a vacuum oven at lower temperatures can be used. Store dried filaments in airtight containers with silica gel packets to prevent reabsorption of moisture. Regularly check for signs of moisture damage, such as brittleness or discoloration. Proper drying ensures consistent print quality and prevents material degradation. Always follow manufacturer guidelines for specific filament types, as some may require different drying conditions. Drying filaments is a simple yet crucial step to achieve optimal printing results and extend the lifespan of your materials.

Optimizing Print Settings for Different Filaments

Optimizing print settings ensures compatibility and quality. Adjust temperature, speed, and layer height based on filament type. Proper settings enhance adhesion, reduce warping, and improve print durability and aesthetics.

Speed Settings

Speed settings play a crucial role in determining print quality and efficiency. Slower speeds are ideal for detailed prints and materials like PLA, while faster speeds suit simpler designs and materials such as ABS. However, excessive speed can lead to poor layer adhesion and reduced print accuracy. It’s essential to balance speed with precision to achieve optimal results. Adjusting speed settings based on filament type ensures smooth extrusion and minimizes the risk of print failures. Additionally, layer-specific speed adjustments can enhance both the overall print quality and printing efficiency. Always refer to filament manufacturer guidelines for recommended speed ranges to maximize performance and durability. Proper speed calibration is key to mastering various filament types and achieving professional-grade prints.

Temperature Settings

Temperature settings are critical for achieving optimal prints, as they directly impact extrusion quality and layer adhesion. Different filaments require specific temperature ranges to ensure proper melting and flow. For example, PLA typically prints between 190°C to 220°C, while PETG ranges from 230°C to 250°C. Higher temperatures can improve flow but may cause issues like stringing or thermal degradation. Conversely, too-low temperatures can result in under-extrusion or poor adhesion. It’s important to calibrate your printer’s temperature settings for each filament type, as even small adjustments can significantly impact print quality. Always refer to the manufacturer’s guidelines for recommended temperature ranges. Additionally, environmental factors, such as using an enclosure, can influence temperature stability and print success. Proper temperature control ensures consistent results and extends the lifespan of your printer and filaments.