The PowerFlex 525 VFD is a versatile and efficient variable frequency drive designed for industrial applications. It offers precise motor control, adjustable frequency, and integrated safety features. The user manual provides essential guidance for installation, operation, and troubleshooting, ensuring optimal performance and safety.

Overview of the PowerFlex 525 Series

The PowerFlex 525 Series is a line of compact AC drives designed for industrial motor control applications. These drives are part of Rockwell Automation’s Allen-Bradley product family and are known for their versatility, reliability, and ease of integration into various industrial systems. The series includes models such as the PowerFlex 523 and PowerFlex 525, catering to different power ratings and application requirements.

The PowerFlex 525 Series is ideal for applications requiring precise speed and torque control, such as pumps, fans, and conveyors. It supports both open-loop and closed-loop control modes, making it suitable for a wide range of industrial processes. The drive’s compact design allows for easy installation in limited spaces, while its robust construction ensures durability in harsh environments.

Key features of the PowerFlex 525 Series include Safe Torque-off (STO) functionality, which enhances safety by removing motor torque when enabled, and a built-in USB programming port for convenient parameter configuration. The series also supports various communication protocols, enabling seamless integration with industrial automation systems. Additionally, the drives are compatible with optional adapters, such as the Embedded EtherNet/IP adapter, for advanced networking capabilities.

For detailed installation, configuration, and operation guidelines, users are encouraged to refer to the PowerFlex 525 user manual, which provides comprehensive instructions and technical specifications. This documentation is essential for ensuring optimal performance and compliance with safety standards.

Overall, the PowerFlex 525 Series is a reliable and flexible solution for industrial motor control, offering advanced features and compatibility with modern automation systems.

Key Features and Benefits of the VFD

The PowerFlex 525 VFD is a high-performance variable frequency drive designed to deliver precise motor control and energy efficiency. It offers a range of advanced features, including Safe Torque-off (STO) functionality, which ensures safe operation by removing motor torque when enabled. This feature is particularly beneficial in applications requiring enhanced safety standards.

Another key benefit is the drive’s compact design, making it ideal for installations where space is limited. The PowerFlex 525 also supports both open-loop and closed-loop control modes, providing flexibility for various industrial applications, such as pumps, fans, and conveyors. Its robust construction ensures reliability in harsh environments, while its user-friendly interface simplifies parameter configuration and monitoring.

The VFD is equipped with a built-in USB programming port, allowing for easy setup and programming without the need for additional software or hardware. Additionally, it supports optional communication adapters, such as the Embedded EtherNet/IP adapter, enabling seamless integration with industrial automation systems. This capability enhances scalability and allows for real-time monitoring and control.

Overall, the PowerFlex 525 VFD is a versatile and efficient solution for industrial motor control, offering advanced features, reliability, and ease of use. Its design and functionality make it a valuable asset for optimizing industrial processes and reducing energy consumption.

Importance of the User Manual

The user manual for the PowerFlex 525 VFD is an essential resource for safe and effective operation. It provides detailed instructions for installation, configuration, and troubleshooting, ensuring that users can maximize the drive’s performance while minimizing risks. The manual includes critical information on safety precautions, such as proper grounding and wiring procedures, to prevent electrical hazards and equipment damage.

One of the key reasons to consult the user manual is to understand the specific features and settings of the PowerFlex 525, such as Safe Torque-off functionality, which is a hardwired feature designed to enhance safety in industrial applications. Additionally, the manual offers guidance on parameter configuration, allowing users to optimize the VFD for their specific motor and application requirements.

For troubleshooting common issues, the manual provides clear diagnostic steps and error codes, helping users quickly identify and resolve problems. It also serves as a reference for compliance with international standards and regulations, ensuring that the drive operates within legal and safety guidelines. By following the manual, users can ensure reliable operation, reduce downtime, and extend the lifespan of the VFD.

Technical Specifications and Installation

The PowerFlex 525 VFD is a compact AC drive designed for open- and closed-loop applications up to 30 hp. It supports various motor control modes and offers flexible mounting options. Installation requires adherence to guidelines in the user manual, including proper grounding and wiring procedures.

Technical specifications, such as voltage, current, and environmental operating conditions, are detailed in the manual. Users must ensure compliance with EMC standards and local regulations. The drive’s compact design and robust construction make it suitable for demanding industrial environments.

Installation Guidelines and Precautions

Proper installation of the PowerFlex 525 VFD is critical to ensure safe and reliable operation. Always refer to the user manual for detailed instructions. Before starting, disconnect the power supply to prevent electrical hazards. Ensure the drive is mounted in a well-ventilated area, away from extreme temperatures and humidity.

Grounding is essential for safety and proper functioning. Connect the drive to a suitable ground point as specified in the manual. Verify that all wiring matches the rated voltage and current of the drive. Use appropriate fuses or circuit breakers to protect the system.

Follow the manual’s guidelines for wiring and terminal connections. Avoid over-tightening terminals, as this can damage the drive. If installing in a hazardous location, ensure compliance with local codes and standards.

After installation, perform a series of tests to verify correct operation. This includes checking output voltage, motor speed, and control functionality. Refer to the manual for specific test procedures and troubleshooting steps.

Improper installation can lead to equipment damage or safety risks. Always adhere to the manufacturer’s instructions and consult qualified personnel if unsure. Regular maintenance, as outlined in the manual, will ensure long-term reliability and performance of the PowerFlex 525 VFD.

Wiring and Commissioning Procedures

Proper wiring and commissioning are essential for the safe and efficient operation of the PowerFlex 525 VFD. Begin by connecting the drive to a suitable power supply, ensuring all terminals are securely fastened. Use the correct gauge of wire for the voltage and current ratings specified in the manual. Proper grounding is critical to prevent electrical noise and ensure safety.

For motor connections, verify that the wiring matches the motor’s nameplate specifications. Use shielded cables for long motor leads to minimize electromagnetic interference. Refer to the manual for specific terminal assignments and wiring diagrams. After completing the wiring, perform a visual inspection to confirm all connections are correct and secure.

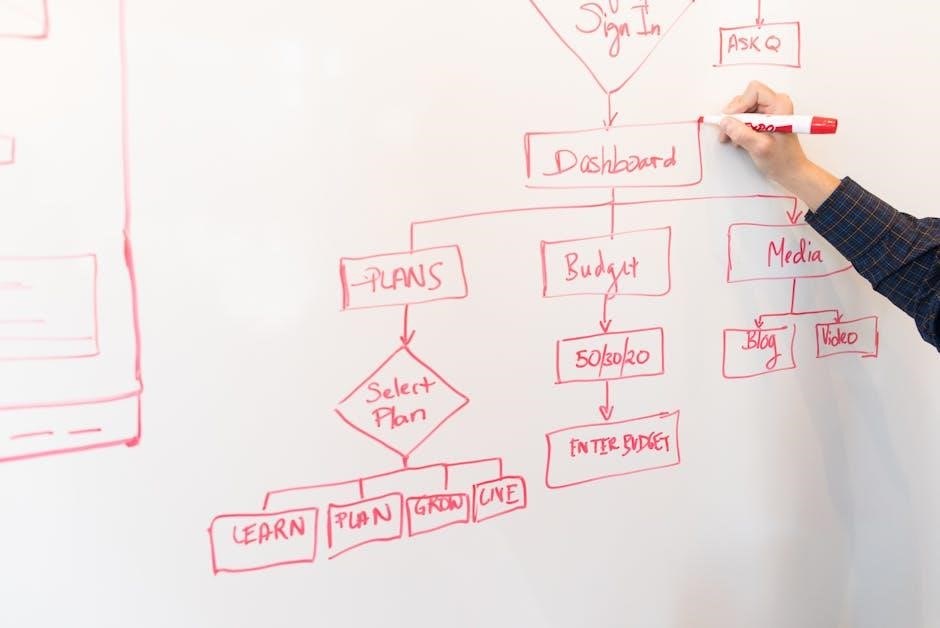

Commissioning involves configuring the drive parameters according to the motor and application requirements. Use the keypad or external programming tools to set the motor nameplate values, such as voltage, current, and frequency. Enable the drive’s control modes, such as constant torque or variable torque, based on the application. Perform a jog test to ensure the motor operates smoothly and in the correct direction.

Monitor the drive’s status during commissioning to identify and resolve any issues promptly. Refer to the user manual for troubleshooting common faults, such as overcurrent or overload conditions. Once the drive is fully commissioned, test it under load to ensure optimal performance and reliability. Always follow safety guidelines and manufacturer recommendations to avoid potential hazards.

Technical Parameters and Configurations

The PowerFlex 525 VFD is designed to meet a wide range of industrial applications, offering flexible technical parameters and configurations. It supports both open-loop and closed-loop control modes, ensuring precise motor speed and torque regulation. The drive is compatible with motors up to 30 horsepower, making it suitable for various industrial machinery.

Key parameters include adjustable frequency ranges, selectable voltage classes, and programmable output frequencies. Users can configure the drive to operate in different control modes, such as constant torque or variable torque, depending on the application requirements. The VFD also supports multiple motor control techniques, including volts per hertz and sensorless vector control.

Advanced configurations include adjustable acceleration and deceleration times, which help protect motors and machinery from sudden starts and stops. The drive also features embedded Ethernet/IP communication capabilities, enabling seamless integration with industrial networks and programmable logic controllers (PLCs). Parameter settings can be customized using the drive’s built-in keypad or external programming software;

Refer to the user manual for detailed technical specifications, including operating voltage ranges, current ratings, and environmental operating conditions. Proper configuration of these parameters is essential to ensure optimal performance, efficiency, and reliability of the PowerFlex 525 VFD in any industrial setting.

Control Modes and Operation

The PowerFlex 525 VFD offers multiple control modes to suit various industrial applications, ensuring precise motor control and operational flexibility. The primary control modes include Volts per Hertz (V/Hz), Sensorless Vector, and Closed-Loop Vector control. V/Hz is ideal for standard applications, providing a cost-effective solution for simple motor speed control.

Sensorless Vector mode enhances performance by estimating motor speed and torque without the need for external sensors, making it suitable for applications requiring higher precision. Closed-Loop Vector control, on the other hand, uses feedback from an encoder or resolver for high-performance applications, offering exceptional speed and torque regulation.

In addition to these control modes, the PowerFlex 525 supports multiple operation modes, including Constant Torque and Variable Torque. Constant Torque mode is designed for applications with consistent load requirements, while Variable Torque mode adapts to changing load demands, optimizing energy efficiency.

The drive also features advanced operation parameters, such as adjustable acceleration and deceleration times, which can be programmed to protect machinery from sudden starts or stops. Furthermore, the PowerFlex 525 allows for manual or automatic control, enabling users to jog the motor or run it continuously as needed.

For detailed instructions on configuring these control modes and operation parameters, refer to the PowerFlex 525 user manual. Proper setup ensures optimal performance, efficiency, and reliability in diverse industrial environments.

Troubleshooting Common Issues

Troubleshooting the PowerFlex 525 VFD involves identifying and addressing common issues that may arise during operation. One frequent problem is motor overload, indicated by an F007 error code. This occurs when the motor load exceeds the drive’s capacity, requiring load reduction or hardware upgrades. Another issue is improper motor direction, which can be resolved by adjusting the reverse run parameter in the control settings.

Users may also encounter communication errors when integrating the VFD with Ethernet/IP networks. This can often be resolved by manually configuring the IP address via the drive’s faceplate or ensuring proper network settings. Additionally, issues with motor speed regulation might stem from incorrect parameter configurations, such as improper acceleration or deceleration times.

The PowerFlex 525 manual provides detailed fault codes and solutions, enabling users to diagnose and resolve problems efficiently. Regularly updating the drive’s firmware and ensuring all connections are secure can prevent many issues. For complex problems, Rockwell Automation offers technical support and resources to assist users in maintaining optimal performance. Always refer to the official user manual for comprehensive troubleshooting guidance.